System Maintenance: 7 Powerful Strategies for Peak Performance

Keeping systems running smoothly isn’t magic—it’s meticulous system maintenance. Whether it’s your computer, server, or industrial machinery, regular upkeep prevents costly breakdowns and boosts efficiency. Let’s dive into the essential practices that keep everything humming.

What Is System Maintenance and Why It Matters

System maintenance refers to the routine activities performed to ensure that hardware, software, and network systems operate efficiently and reliably. It’s not just about fixing problems—it’s about preventing them before they occur. In both IT and industrial environments, system maintenance is the backbone of operational continuity.

Defining System Maintenance

At its core, system maintenance involves inspecting, testing, repairing, and upgrading systems to maintain optimal performance. This includes everything from updating software patches to cleaning physical components. The goal is to extend the lifespan of systems while minimizing downtime and security risks.

- Applies to both digital (servers, networks) and physical (machinery, HVAC) systems

- Includes preventive, corrective, predictive, and adaptive approaches

- Essential for compliance, security, and operational efficiency

“Maintenance is not a cost—it’s an investment in reliability.” — Industry Expert

The Business Impact of Neglecting Maintenance

Ignoring system maintenance can lead to catastrophic failures. A 2022 report by Gartner found that unplanned downtime costs enterprises an average of $5,600 per minute. Beyond financial loss, poor maintenance can damage customer trust, violate regulatory standards, and compromise data security.

- Increased risk of data breaches due to unpatched software

- Higher repair costs from delayed interventions

- Reduced employee productivity during system outages

For example, a major airline once grounded hundreds of flights due to a single server failure caused by outdated firmware—highlighting how critical proactive system maintenance truly is.

Types of System Maintenance

Not all maintenance is the same. Different scenarios call for different strategies. Understanding the types of system maintenance helps organizations choose the right approach for their needs.

Preventive Maintenance

Preventive maintenance is scheduled work done to prevent equipment failure before it happens. This includes regular inspections, software updates, and hardware cleanings. It’s like changing your car’s oil every 3,000 miles—it keeps things running smoothly.

- Reduces unexpected breakdowns

- Extends equipment lifespan

- Improves safety and compliance

According to the U.S. Department of Energy, preventive maintenance can reduce energy consumption by up to 12% in industrial systems. For IT systems, this might mean scheduling monthly patch updates or quarterly disk cleanups.

Corrective Maintenance

Corrective maintenance is reactive—it happens after a failure occurs. While unavoidable at times, relying too heavily on this type can be costly and disruptive. It involves diagnosing issues, replacing faulty components, and restoring functionality.

- Often more expensive than preventive measures

- Can lead to extended downtime

- Necessary for unforeseen hardware or software crashes

For instance, if a database server crashes due to a corrupted file, corrective maintenance would involve restoring from backup and fixing the root cause.

Predictive and Adaptive Maintenance

Predictive maintenance uses data and analytics to forecast when a system might fail. Sensors, machine learning, and performance logs help identify patterns that precede failures. Adaptive maintenance, on the other hand, modifies systems to meet changing requirements—like upgrading software to support new features.

- Leverages IoT and AI for real-time monitoring

- Reduces unnecessary maintenance tasks

- Supports scalability and future-proofing

A study by McKinsey showed that predictive maintenance can reduce maintenance costs by 10–40% and downtime by 50%. Companies like Siemens and GE use these techniques in manufacturing and energy sectors.

System Maintenance in IT Infrastructure

In the digital world, system maintenance is crucial for keeping networks, servers, and applications secure and functional. As cyber threats evolve and technology advances, maintaining IT systems is more complex than ever.

Server and Network Maintenance

Servers and networks form the backbone of modern businesses. Regular maintenance ensures they remain fast, secure, and available. Tasks include updating firmware, monitoring bandwidth usage, and checking firewall configurations.

- Apply security patches promptly (e.g., Microsoft Patch Tuesday)

- Monitor network traffic for anomalies

- Conduct regular backups and disaster recovery drills

The Cybersecurity and Infrastructure Security Agency (CISA) recommends quarterly vulnerability assessments as part of routine system maintenance.

Software Updates and Patch Management

Software doesn’t stay secure forever. Developers release patches to fix bugs and close security holes. Effective patch management is a key component of system maintenance in IT environments.

- Automate updates where possible using tools like WSUS or SCCM

- Test patches in a staging environment before deployment

- Prioritize critical updates (e.g., zero-day vulnerabilities)

For example, the 2017 WannaCry ransomware attack exploited a known Windows vulnerability that had a patch available—but many organizations hadn’t applied it, leading to global disruptions.

Database Maintenance

Databases store critical business information. Without proper maintenance, they can become slow, corrupt, or vulnerable to attacks. Regular tasks include indexing, defragmentation, and integrity checks.

- Run DBCC CHECKDB on SQL Server to detect corruption

- Rebuild indexes to improve query performance

- Schedule regular backups with offsite storage

According to IBM, the average cost of a data breach in 2023 was $4.45 million—making database maintenance not just technical, but financial risk management.

Industrial and Mechanical System Maintenance

Beyond computers, system maintenance applies to physical machinery in factories, power plants, and transportation systems. Here, the stakes are high—equipment failure can lead to injuries, environmental damage, or production halts.

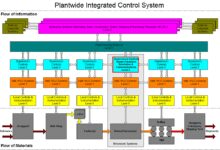

Maintenance in Manufacturing

In manufacturing, machines run 24/7. Preventive maintenance schedules are critical to avoid costly line stoppages. Techniques include lubrication, alignment checks, and vibration analysis.

- Use CMMS (Computerized Maintenance Management Systems) to track work orders

- Train technicians on standard operating procedures

- Integrate sensors for real-time equipment health monitoring

Toyota’s famous “Total Productive Maintenance” (TPM) philosophy empowers every employee to participate in equipment care, reducing downtime and improving quality.

HVAC and Building Systems

Heating, ventilation, and air conditioning (HVAC) systems require regular maintenance to operate efficiently. Dirty filters, refrigerant leaks, and worn belts can increase energy costs and reduce indoor air quality.

- Replace filters every 1–3 months

- Inspect ductwork for leaks

- Calibrate thermostats annually

The U.S. Environmental Protection Agency (EPA) estimates that proper HVAC maintenance can save up to 30% on energy bills. Learn more at Energy Star.

Transportation and Fleet Maintenance

Fleets of vehicles—whether delivery trucks or public transit—rely on strict maintenance schedules. System maintenance here includes engine diagnostics, tire inspections, and emission testing.

- Use telematics to monitor vehicle health in real time

- Schedule oil changes and brake checks based on mileage

- Keep digital logs for compliance and audits

Companies like UPS use predictive analytics to determine when a truck needs servicing, reducing roadside breakdowns by over 50%.

Best Practices for Effective System Maintenance

Successful system maintenance isn’t just about doing tasks—it’s about doing them right. Following best practices ensures consistency, accountability, and long-term success.

Create a Maintenance Schedule

A well-structured maintenance schedule is the foundation of any effective program. It outlines when tasks should be performed, who is responsible, and what tools are needed.

- Use a calendar-based or usage-based trigger system

- Include both daily checks and annual overhauls

- Integrate with project management tools like Jira or Trello

For IT teams, a monthly maintenance window (e.g., first Sunday of the month) helps standardize updates without disrupting business hours.

Document Everything

Documentation is often overlooked but vital. It provides a history of repairs, upgrades, and performance trends. This information is invaluable for troubleshooting and audits.

- Maintain logs for all maintenance activities

- Store manuals and schematics digitally

- Use version control for configuration files

“If it wasn’t documented, it didn’t happen.” — IT Operations Mantra

Train and Empower Your Team

Even the best tools fail without skilled people. Training ensures that staff understand procedures, safety protocols, and the importance of system maintenance.

- Offer certifications (e.g., CompTIA, AWS, OSHA)

- Conduct regular workshops and drills

- Encourage cross-training to avoid single points of failure

Google’s Site Reliability Engineering (SRE) model emphasizes shared responsibility for system health, reducing silos between development and operations teams.

Tools and Technologies for System Maintenance

Modern system maintenance relies on specialized tools to automate, monitor, and optimize processes. From software platforms to physical diagnostic devices, the right tools make all the difference.

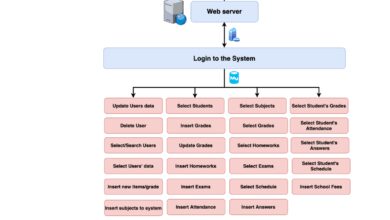

Maintenance Management Software

Computerized Maintenance Management Systems (CMMS) and Enterprise Asset Management (EAM) platforms help organizations track, schedule, and analyze maintenance activities.

- Examples: UpKeep, Fiix, IBM Maximo

- Features include work order tracking, inventory management, and reporting

- Cloud-based options enable mobile access for field technicians

These tools integrate with IoT devices to provide real-time alerts and predictive insights.

Monitoring and Diagnostic Tools

For IT systems, tools like Nagios, Zabbix, and SolarWinds provide continuous monitoring of servers, networks, and applications. They alert administrators to issues like high CPU usage or disk space shortages.

- Set up dashboards for real-time visibility

- Configure alerts via email or SMS

- Use historical data to identify trends

In industrial settings, vibration analyzers, thermal cameras, and oil analysis kits help detect mechanical wear before failure.

Automation and AI in Maintenance

Artificial intelligence is transforming system maintenance. Machine learning models analyze vast amounts of data to predict failures, optimize schedules, and recommend actions.

- AI-powered chatbots assist with troubleshooting

- Predictive algorithms reduce unnecessary maintenance

- Robotic Process Automation (RPA) handles repetitive tasks

Microsoft’s Azure AI offers predictive maintenance solutions for manufacturing and energy sectors, helping companies save millions annually.

Common Challenges in System Maintenance

Even with the best plans, organizations face obstacles in maintaining their systems effectively. Recognizing these challenges is the first step toward overcoming them.

Budget Constraints

Many organizations underfund maintenance, viewing it as a cost rather than an investment. This leads to deferred maintenance, which accumulates into larger, more expensive problems.

- Present ROI data to justify maintenance spending

- Start small with high-impact, low-cost initiatives

- Seek grants or tax incentives for energy-efficient upgrades

A 2021 Deloitte study found that every $1 invested in preventive maintenance saves $4 in corrective costs.

Skill Gaps and Staffing Issues

Finding and retaining skilled technicians is a growing challenge. As systems become more complex, the demand for expertise in IT, robotics, and data analytics increases.

- Partner with technical schools for training pipelines

- Offer competitive wages and career development

- Use remote expert support via AR/VR tools

Some companies use digital twins—virtual replicas of physical systems—to train staff in simulated environments.

Resistance to Change

Employees may resist new maintenance procedures or technologies due to fear of job loss or unfamiliarity. Leadership must communicate the benefits clearly and involve teams in the transition.

- Run pilot programs to demonstrate success

- Recognize and reward early adopters

- Provide ongoing support and feedback channels

“The biggest risk is not taking any risk. In a world that’s changing quickly, the only strategy that is guaranteed to fail is not taking risks.” — Mark Zuckerberg

Future Trends in System Maintenance

The field of system maintenance is evolving rapidly. Emerging technologies and changing business models are shaping how organizations approach upkeep and reliability.

Internet of Things (IoT) Integration

IoT devices are revolutionizing maintenance by providing real-time data from sensors embedded in equipment. This enables continuous monitoring and faster response times.

- Sensors track temperature, pressure, vibration, and more

- Data is sent to cloud platforms for analysis

- Alerts are triggered when thresholds are exceeded

For example, smart elevators can report wear on cables before they snap, allowing preemptive repairs.

Green and Sustainable Maintenance

As sustainability becomes a priority, organizations are adopting eco-friendly maintenance practices. This includes using energy-efficient parts, recycling materials, and reducing waste.

- Replace old motors with energy-saving models

- Use biodegradable lubricants

- Optimize maintenance routes to reduce fuel consumption

The United Nations Environment Programme promotes sustainable maintenance as part of broader climate goals.

Remote and Autonomous Maintenance

With advancements in robotics and remote access, some maintenance tasks can now be performed without human presence. Drones inspect wind turbines, while remote IT teams fix servers from thousands of miles away.

- Reduces travel costs and response time

- Enables maintenance in hazardous environments

- Supports global operations with local execution

Amazon uses autonomous robots in its warehouses to perform routine checks, minimizing human intervention.

What is the most important type of system maintenance?

Preventive maintenance is often considered the most important because it stops problems before they occur, reducing downtime and costs. However, a balanced approach that includes predictive and corrective strategies is ideal for comprehensive system health.

How often should system maintenance be performed?

The frequency depends on the system. IT systems may need weekly updates and monthly checks, while industrial machinery might require daily inspections and annual overhauls. Always follow manufacturer guidelines and industry best practices.

Can system maintenance prevent cyberattacks?

Yes. Regular patching, software updates, and security audits are critical components of system maintenance that directly reduce the risk of cyberattacks by closing known vulnerabilities.

What is the cost of skipping system maintenance?

Skipping maintenance leads to higher repair costs, extended downtime, data loss, and security breaches. Gartner estimates that unplanned downtime costs businesses over $300,000 per hour on average.

Is AI replacing human maintenance workers?

No, AI is not replacing humans but augmenting their capabilities. AI handles data analysis and predictions, while humans make strategic decisions, perform complex repairs, and manage systems. The future is collaboration, not replacement.

System maintenance is far more than a technical checklist—it’s a strategic necessity. From preventing cyber threats to ensuring machinery runs smoothly, proactive upkeep saves time, money, and reputational risk. By embracing best practices, leveraging modern tools, and preparing for future trends, organizations can achieve peak performance and long-term reliability. The key is consistency, documentation, and a culture that values prevention over reaction. In a world where systems are more interconnected than ever, robust system maintenance isn’t optional—it’s essential.

Further Reading: